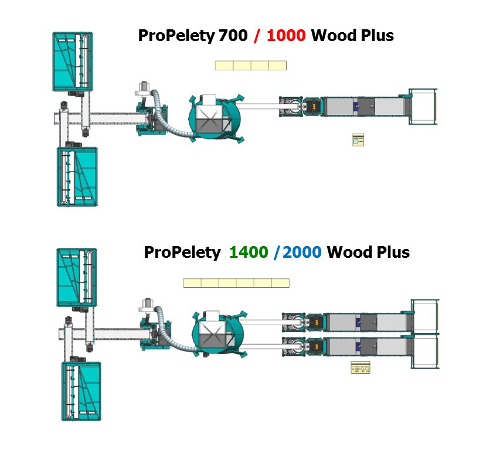

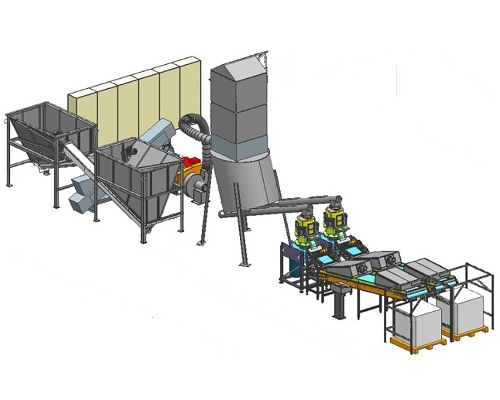

Pellet production line ProPelety Wood Plus Basic / Power / Basic Duo / Power Duo

Pellet production line for two types of sawdust or shavings.

Pellet production line for two types of sawdust or shavings.

Sawdust or wood shavings (waste from cutting or planed dry wood). In case of higher humidity, the input material must be dried to the required humidity of max. 14%.